Performance-based approaches for high strength tubular columns and connections under earthquake and fire loadings (ATTEL)

Sponsor:

European Commission

Program:

RFSR-CT-2008-00037

Partners:

University of Liege, Belgium

Centro Sviluppo Materiali, Italy

Stahlbau Pichler, Italy

University of Thessaly, Greece

University of Trento, Italy.

Objective:

The project ATTEL intends to develop both analytical and experimental know-how in order to support new design criteria for the exploitation of HSS and steel-concrete composite circular hollow sections for columns and connections subjected to exceptional loads, like earthquakes and fire. The investigation will be both experimental, through testing of tubular members and connections, analytical and numerical, through the use of the component method and advanced finite element simulations, in order to make full use of high strength steel ranging from S500Q/S500MC to S690Q/S700MC according to Eurocode 3 Part 1-12, for structural tubes ranging from 2 in to 24 in, with D/t > 30; in a greater detail, over-design based approaches are going to be applied for:

1. Steel and composite CFT columns made of HSS;

2. Welded or bolted composite beam-to-CFT column joints made of HSS;

3. CFT column base-joints made of HSS.

In detail, results coming from the experimental, numerical and analytical studies will:

i) Improve knowledge on the performance of HSS elements under seismic action, getting over the misconception that the ultimate-to-yield ratio is an important factor for avoiding premature local buckling in the inelastic range; thus, the will is to demonstrate that a plastic hinge analysis is possible with HSS.

Eliminate fire protection in conventionally designed and built steel-framed buildings, by

i) achieving a better understanding of the whole building behaviour;

ii) characterizing the HSS material with regard to the mechanical properties evolution with temperature; and

iii) developing a full fire engineering approach based on the over-design methodology.

Principal Investigator for U.Th.:

Spyros A. Karamanos

Total Budget:

1,148,834 Euros

U.Th. Budget:

186,848 Euros

Duration:

42 months (2008 - 2011)

Figures:

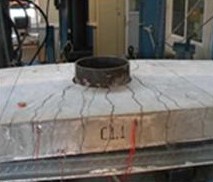

Figure 1: (a) Initial configuration, (b) cracking propagation and (c) excessive cracking and deformation of slab specimens

Figure 2: Test setup for beam-to-column component.

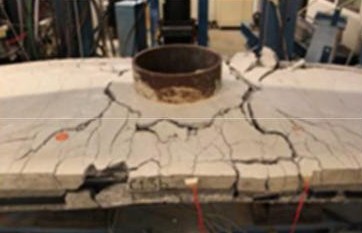

Figure 3: (a) Deformed beam-to-column specimen and (b) buckling of through-plate inside the tube.

Figure 4: (a) Deformed base-plate specimen and (b) failure mode of base plate.

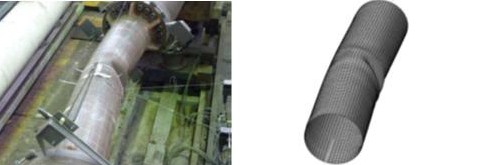

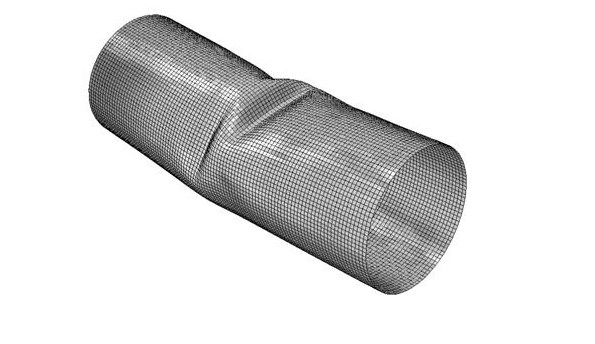

Figure 5: Buckled shape for a 1.5m-long specimen of 0323.9/10 section under

combined loading in comparison with the FE model.

Figure 6: Buckled shape for the 0355.6/12.5 1.5m-long specimen under axial compression

in comparison with the FE model.

Figure 7: Local Buckling of a short tubular member 0355.6/12.5 under axial compression