Strain-based design of spiral-welded pipes for demanding pipeline applications (SBD-SPIPE)

Sponsor:

European Commission

Program:

RFSR-CT-2013-00025

Partners:

CENTRO SVILUPPO MATERIALI SPA , Italy

Corinth Pipeworks S.A., Creece

Instytut Spawalnictwa, Poland

OCAS - ONDERZOEKSCENTRUM VOOR AANWENDING VAN STAAL N.V., Belgium

Salzgitter Mannesmann Forschung GmbH, Germany

UNIVERSITEIT GENT, Belgium

Panepistimio Thessalias (University of Thessaly)

Objective:

The oil and gas operating companies are nowadays more and more interested in using also spirally welded pipes for transportation of energetic fluids over long distances. In fact, the enhancement in the metallurgical process and quality of this kind of product led to improved performance especially related to structural integrity issues, also for higher grade steels. The use of spirally welded pipes (HSAW) for pipeline construction, in addition to pipes produced through different technologies which often require complex and huge rolling plants, allows taking advantage of a wider production capacity worldwide. Nowadays there are a number of spirally welded pipe producers in the world and in Europe in particular. On the other hand, a series of long HSAW pipelines are under construction or planned for the future.

The general aim of this project is to develop specific know-how concerning the possible use of spirally welded pipes for demanding in-service applications, both onshore and offshore, requiring high strain performances. In particular, the activities proposed are aimed at filling the existing lack of information about structural integrity issues, thus completing the know-how for a safe and reliable use of this kind of product also for challenging applications. The outcomes of this project can also be used as a technical basis for improving existing international guidelines and codes addressing the design and safety of gas pipelines.

The specific goals of this project will be the following:

- To develop a suitable and validated numerical approach to evaluate the strain behaviour of spirally welded pipes when external combined loads (forces and/or displacements) are applied. A commercial finite element code will be used coupled with new and advanced models and criteria to reproduce material damage in plastic regime. In detail, the following “limit states” will be taken into account:

─ Local plastic instability (buckling) due to bending also in biaxial conditions (combined loading);

─ Plastic collapse due to external pressure;

─ Tensile tearing due to axial tension. The integrity of both parent pipe and girth welded joints will be studied.

- To develop assessment criteria for the evaluation of defect acceptability in spiral welded joints subjected to remote strain higher that 2%.

- To develop criteria to quantify the role that residual stress, anisotropy of mechanical properties, geometrical tolerances (both in terms of ovalization of pipe and weld misalignment) can play on the strain capacity of spiral welded pipes.

To achieve the objectives listed above, small scale and full scale laboratory testing program will be carried out on spirally welded pipes in steel grade API X60 ÷ X80 and geometry ranging from 24” to 48” of outer diameter and 13 to 20 mm of wall thickness..

Principal Investigator for U.Th.:

Spyros A. Karamanos

Total Budget:

1,910,794.00 Euros

U.Th. Budget:

168,334.00 Euros

Duration:

36 months (2013 - 2016)

Figures:

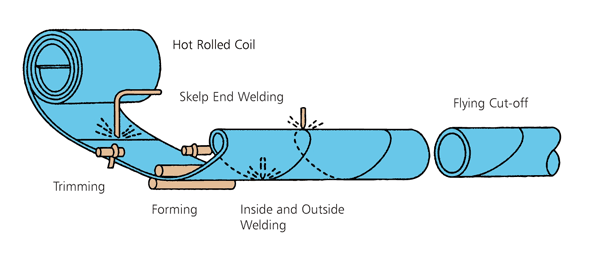

Figure 1: Spiral-Welded Pipe manufacturing process.

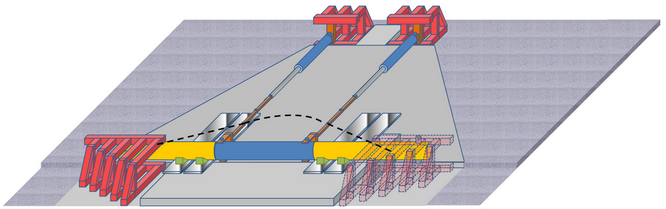

Figure 2: Set-up for full-scale tests of pipes under pressurized bending in CSM.