Design and integrity assessment of high strength tubular structures for extreme loading conditions (HITUBES)

Sponsor:

European Commission

Program:

RFSR-CT-2008-00035

Partners:

University of Liege, Belgium

Centro Sviluppo Materiali, Italy

Stahlbau Pichler, Italy

University of Thessaly, Greece

University of Trento, Italy

KIMAB, Sweden

ISQ, Portugal

ITMA, Spain

Objective:

Objective 1 - To develop designs and assessment procedures in order to make full use of high strength steel ranging from S500Q/ S500MC to S690Q/S700MC according to the new Eurocode 3 Part 1-12 (Additional rules for the extension of EN 1993 up to steel grades S 700), mainly for structural tubes ranging from 2 in to 24 in with D/t > 30 for onshore structures.

Objective 2 - To increase structural performance of structures, reduce weights, construction and operating costs.

Principal Investigator for U.Th.:

Spyros A. Karamanos

Total Budget:

1,478,537 Euros

U.Th. Budget:

180,544 Euros

Duration:

42 months (2008 - 2011)

Figures:

Figure 1: General view of the test set-up with the specimens for:

(a) out-of-plane bending tests, (b) in-plane bending tests.

Figure 2: Uniaxial 5-element strip strain gages at:

(a) the hoop direction of the chord, (b) the meridional direction of the chord

Figure 3: (a) OPB specimen at failure, (b) failure crack of OPB specimen.

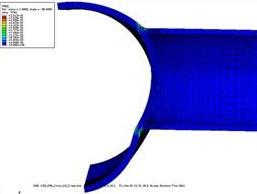

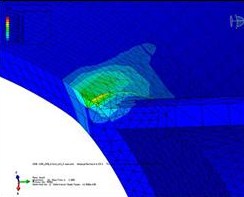

Figure 4: Out-of-plane bending test simulation. Mid-span section (a) Deformed chord geometry

(b) Equivalent plastic strain distribution at the weld-toe area.

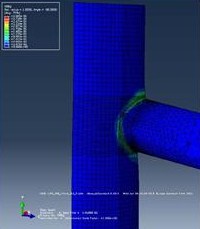

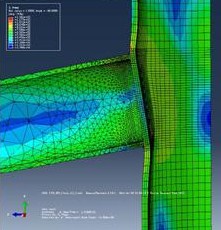

Figure 5: In-plane bending test simulation. (a) Equivalent plastic strain distribution at the weld-toe area,

(b) Deformed chord geometry - mid-span section.