Finite element Simulation of UOE Pipe Manufacturing Process

Summary:

A significant number of large-diameter-thickness line pipes used in offshore applications are commonly manufactured by cold-forming plates through the UOE process, consisting of four sequential forming steps. In this research, the UOE forming process is modeled numerically through the application of a non-linear finite element program, and focuses on the effect of the manufacturing process on the buckling pressure and the bending capacity of the offshore pipeline.

Special emphasis is given on the constitutive model for the accurate description of inelastic steel behavior due to reverse plastic loading; a special-purpose model is developed, based on nonlinear kinematic hardening, capable of describing the plastic plateau at initial yielding of the steel plate, as well as the Bauschinger effect. In addition, a parametric analysis is also conducted focusing on the effects of line pipe expansion on the structural capacity of the pipe.

As a result, there exists an optimum expansion at which highest resistance in pressure loading is achieved. For combined pressure-bending loading conditions, and for relatively low external pressure levels, UOE pipes exhibit high bending deformation capacity. On the contrary, as the pressure level increases, UOE pipes are less resistant to bending loads. The developed numerical simulation is able to describe the effects of UOE manufacturing process on the overall structural behavior of the pipe and can be a powerful tool for identifying the values for the manufacturing parameters that optimize pipe performance in terms of pressure and bending load capacity.

People:

Giannoula Chatzopoulou

Spyros A. Karamanos

Relevant Publications:

In Conference Proceedings

- Chatzopoulou G., Varelis G. E., Karamanos S. A. (2014), “Effects of UOE manufacturing process on pressurized bending response of offshore pipes”, 10th International Pipeline Conference, IPC2014-33321, Calgary, Canada.

- Chatzopoulou G., Karamanos S. A., Varelis G. E. (2014), “Finite Element Analysis of UOE Pipes under External Pressure and Bending”, 24th International Ocean and Polar Engineering Conference, ISOPE-2014 Busan, S. Korea.

Figures:

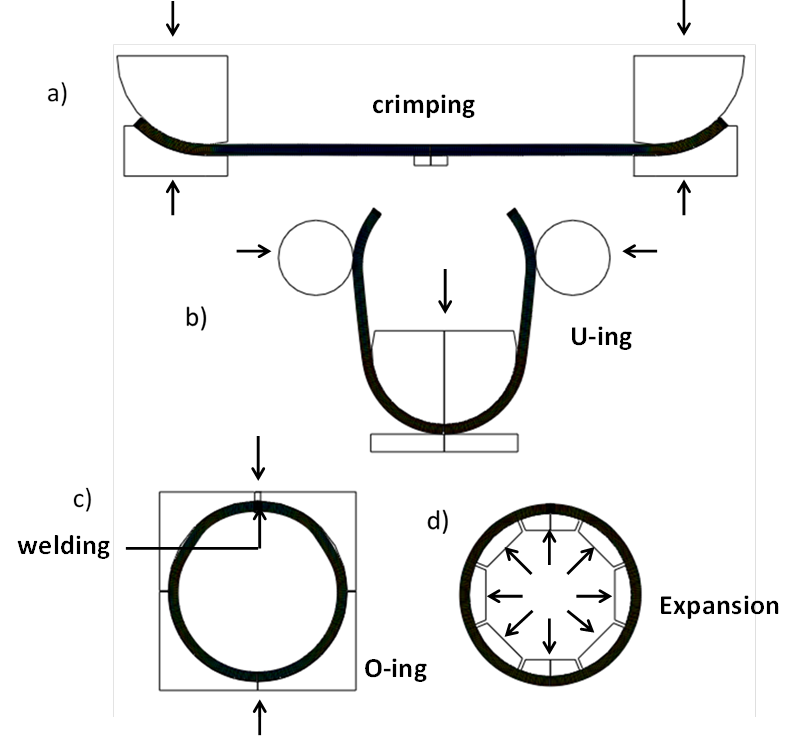

Figure 1: Schematic representation and main parameters of UOE forming steps: a) Crimping press, b) U-press, c) O-press, d) Expansion.

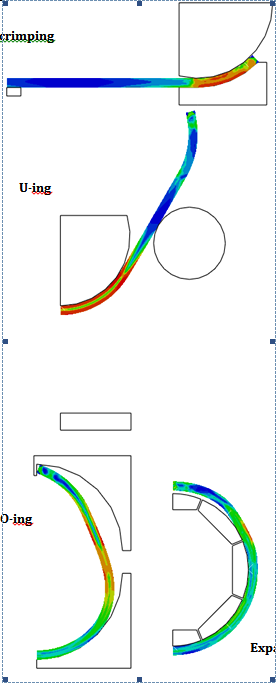

Figure 2: Numerical simulation of UOE process.