Mechanical Behavior and Wrinkling of Lined Pipes under Bending and External Pressure

Summary:

The research examines the mechanical behavior of lined pipes and investigates extensively the wrinkling of such pipes under bending loading with or without the presence of external pressure. Lined pipe, also referred to as “mechanically clad pipe”, is a new and promising technological solution in energy pipeline applications where the structural integrity of oil and gas steel pipelines requires erosion damage protection from oil or gas pollutants. Lined pipe is a double-wall pipe, consisting of a load-bearing high-strength, low-alloy carbon steel outer pipe, lined with a thin-walled sleeve made from a corrosion-resistant material referred to as “liner” pipe. Lined pipes are produced through an appropriate manufacturing procedure, consisting of heating the outer pipe, inserting the liner and pressurizing it until both pipes come to contact, and finally cooling the outer pipe. Considering the liner pipe as a thin-walled cylindrical shell prone to buckling, the lateral confinement due to the deformable outer pipe constitutes a paramount parameter for its mechanical behavior. In the present investigation, the problem is solved numerically, using nonlinear finite elements capable at simulating the lined pipe and the interaction between the liner and the outer pipe. Nonlinear geometry with large strains is taken into account, and the material of both pipes is elastic-plastic. The lined pipe is considered either stress-free (snug-fit pipe, SFP) or with an initial stress (tight-fit pipe, TFP). The thermo-hydraulic manufacturing process of the lined pipe is simulated to determine the liner hoop prestressing. First, an ovalization bending analysis of the lined pipe is conducted, where a slice of the pipe between two adjacent cross-sections is considered excluding the possibility of buckling. In this analysis, the stress and deformation of the liner in the compression zone is monitored, with emphasis on possible detachment of the liner from the outer pipe. Using a simple buckling hypothesis, it is possible to estimate the curvature at which liner wrinkling would occur. Subsequently, a three-dimensional analysis is conducted to examine buckling of the liner in the form of a uniform wrinkling pattern. The curvature at which buckling occurs and the corresponding buckling wavelength are determined for different thicknesses of the liner and outer pipe. Furthermore, the transition from a uniform wrinkling configuration to a secondary bifurcation with more localized deformations is investigated, and reference to experimental observations is made. Next, the effects of initial imperfections on the structural behavior of lined pipes are investigated. Subsequently, the effect of the prestressing on the critical wavelength and the buckling curvature is examined. A comparison with available experimental results is conducted in terms of wrinkle height development and the corresponding buckling wavelength. Finally, the structural behavior of lined steel pipes under bending in the presence of external pressure is examined. The results of the present research can be used for safer design of lined pipes in pipeline applications.

People:

Daniel Vasilikis

Spyros A. Karamanos

Relevant Publications:

In Referred Journals

- Vasilikis, D. and Karamanos, S.A., “Mechanical Behavior and Wrinkling of Lined Pipes”, International Journal of Solids and Structures, Vol. 49, No. 23-24, pp. 3432-3446, November 2012.

- Vasilikis, D. and Karamanos, S.A., “Buckling of Double-Wall Elastic Tubes under Bending”, 9th HSTAM International Congress on Mechanics, Limassol, Cyprus, July 2010.

- Vasilikis, D. and Karamanos, S.A., “Buckling of Clad Pipes under Bending and External Pressure”, 30th International Conference on Ocean, Offshore and Arctic Engineering, ASME, OMAE2011-49470, Rotterdam, The Netherlands, June 2011.

- Vasilikis, D. and Karamanos, S.A., “Numerical Simulation of Clad Pipe Structural Behavior under Bending Loading”, 7th GRACM International Congress on Computational Mechanics, Athens, Greece, June 2011.

- Vasilikis, D. and Karamanos, S.A., “Wrinkling of Lined Pipes under Bending”, 22nd International Conference on Offshore (Ocean) and Polar Engineering, ISOPE2012-TCP-0748, Rhodes, Greece, June 2012.

In Conference Proceedings

Figures:

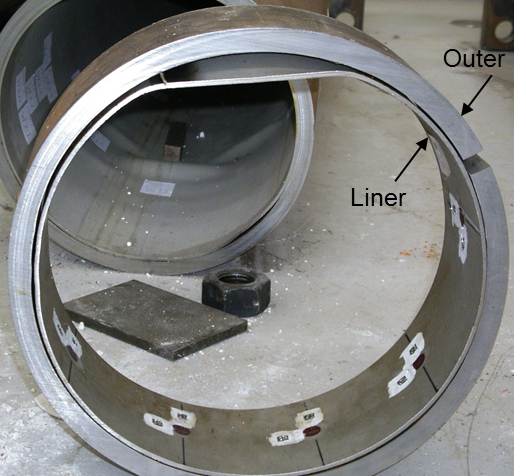

Figure 1: Photo of lined pipes after experimental testing.

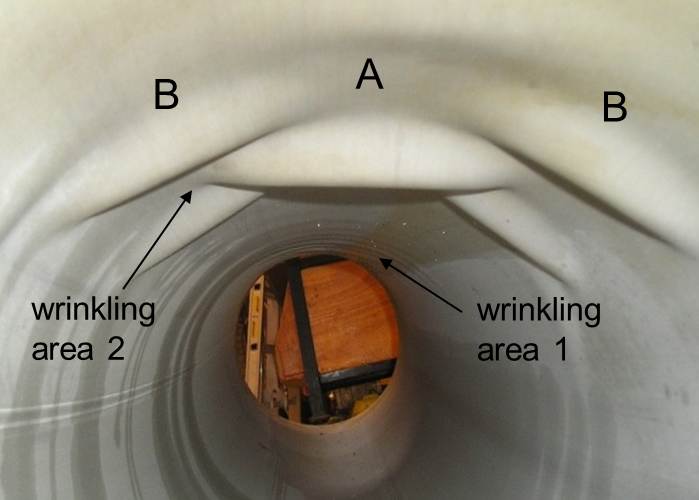

Figure 2: Photo of wrinkled liner pipe after experimental testing.

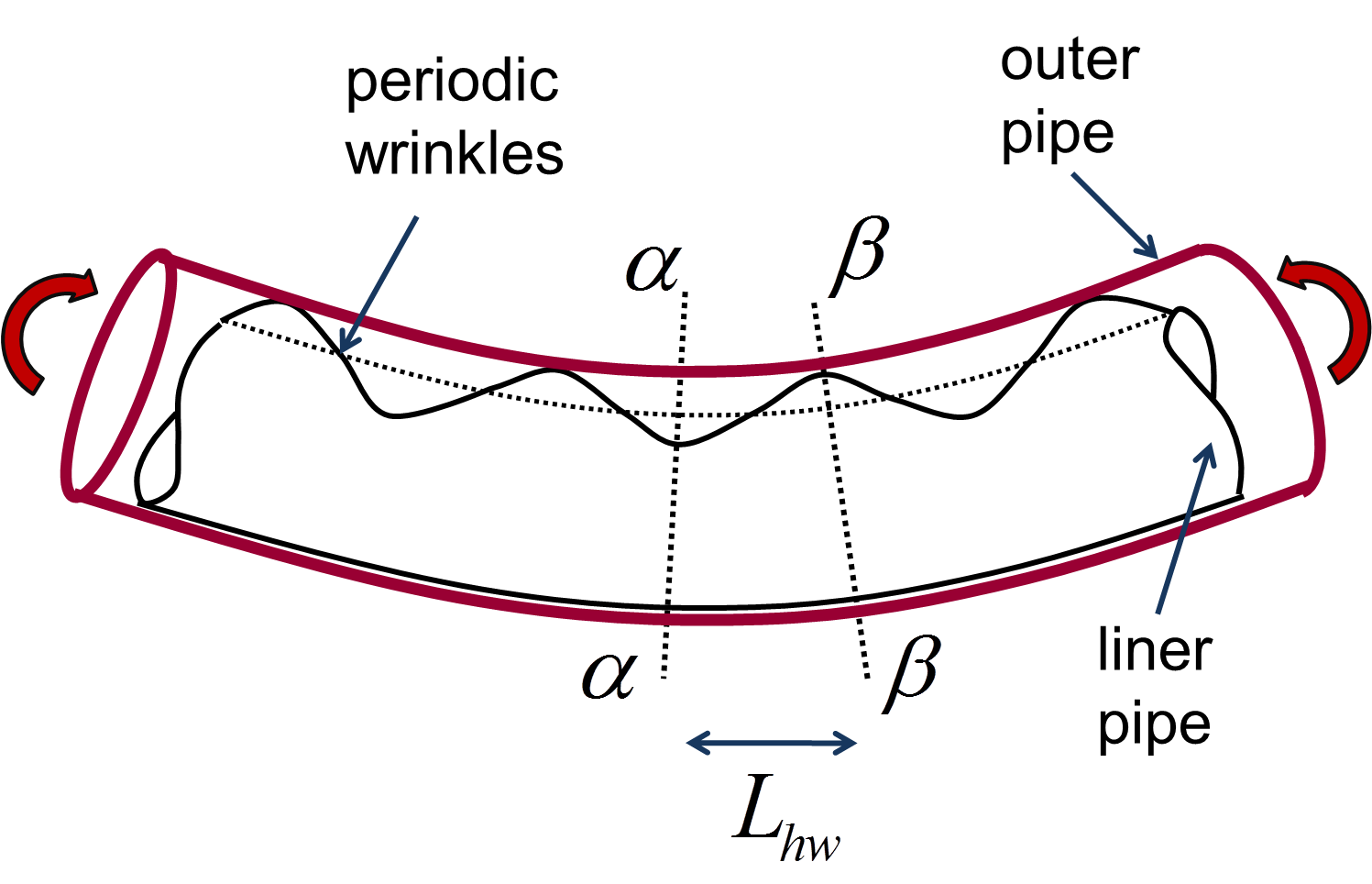

Figure 3: Schematic representation of uniformly wrinkled pipe and the corresponding half-wavelength between cross-sections α-α and β-β.

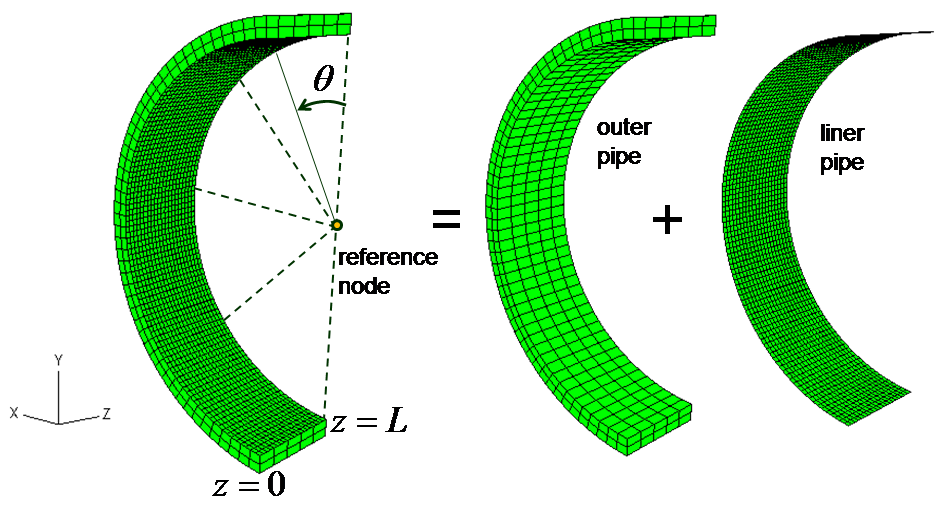

Figure 4: Lined pipe model; outer pipe is modeled with solid elements and liner pipe is modeled with shell elements.

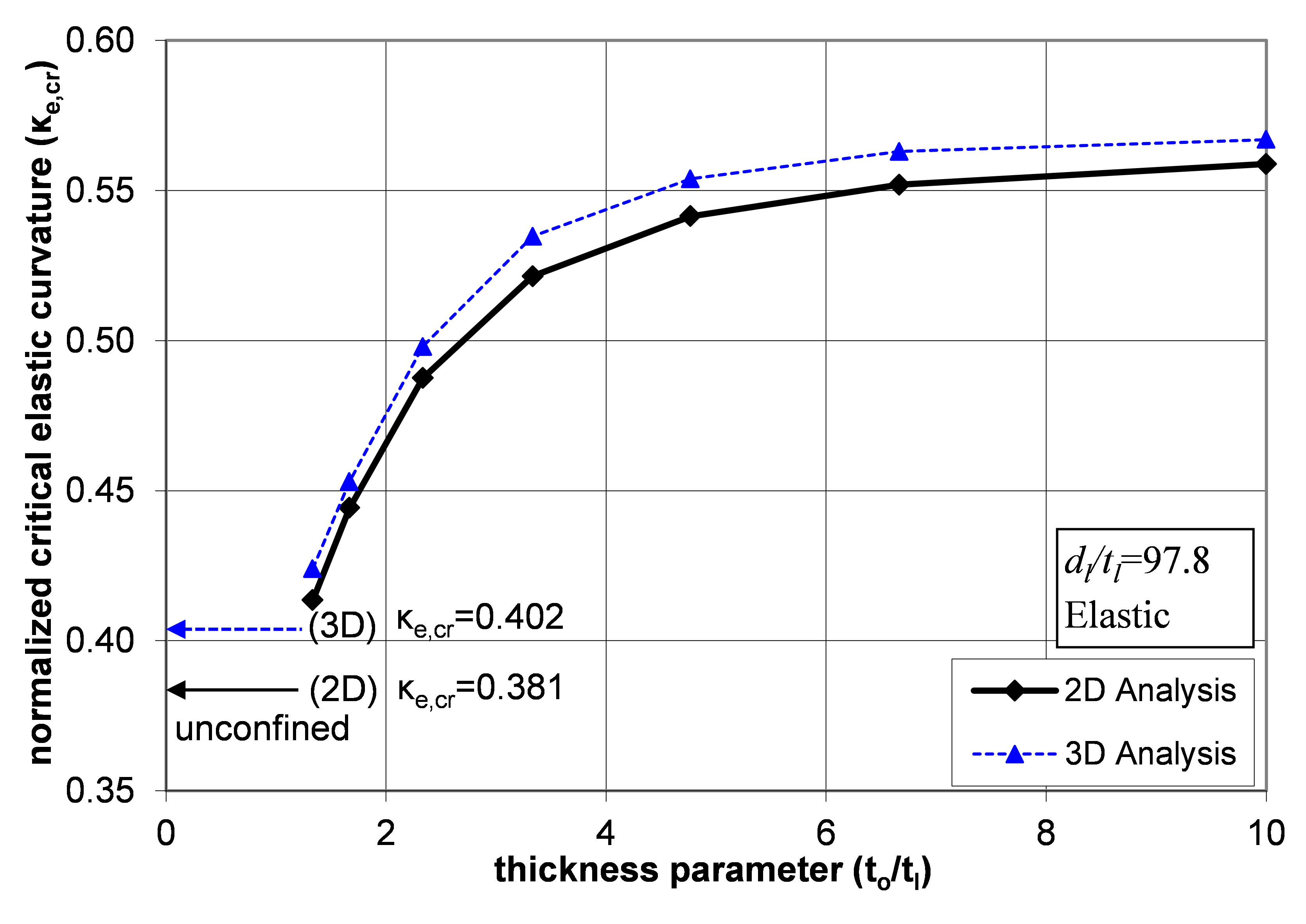

Figure 5: Variation of the normalized critical curvature for different thicknesses of the outer pipe.

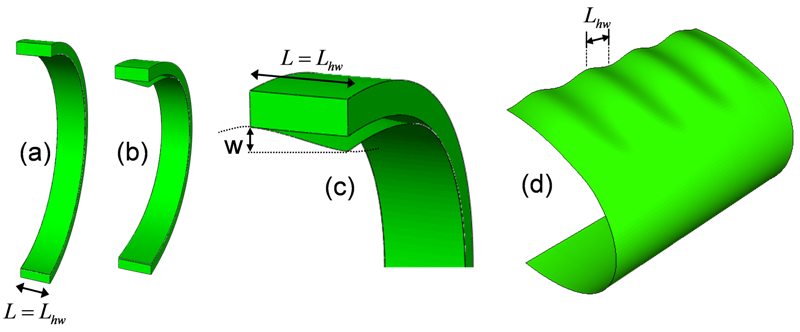

Figure 6: Lined pipe configurations; (a) undeformed configuration; (b), (c) and (d) ovalized and buckled liner.

Figure 7: (a) Initial configuration with liner wavy imperfection and (b),(c),(d) Deformed (buckled) configuration of lined pipe after secondary bifurcation.

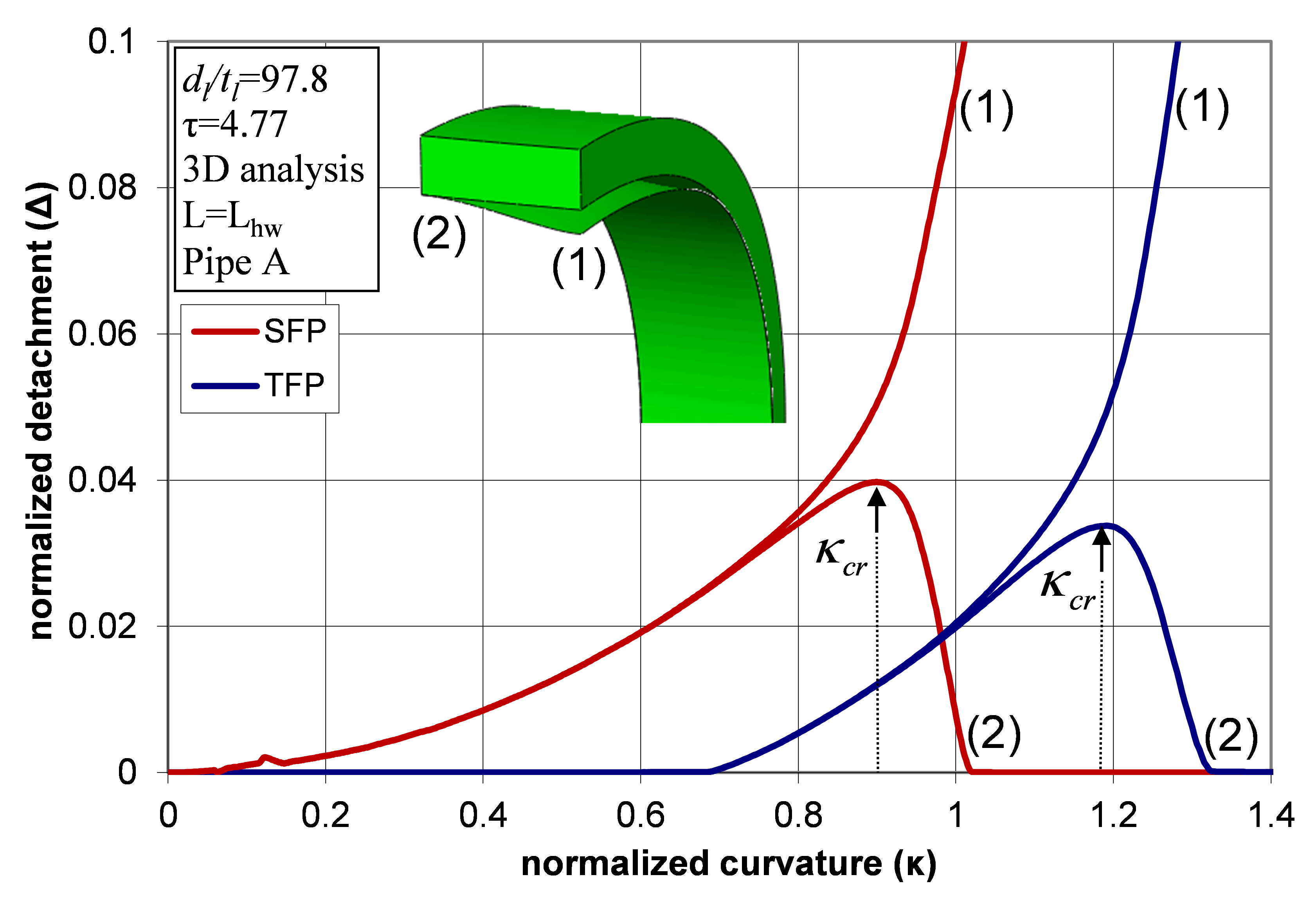

Figure 8: Detachment development of points (1) and (2) in terms of bending curvature.

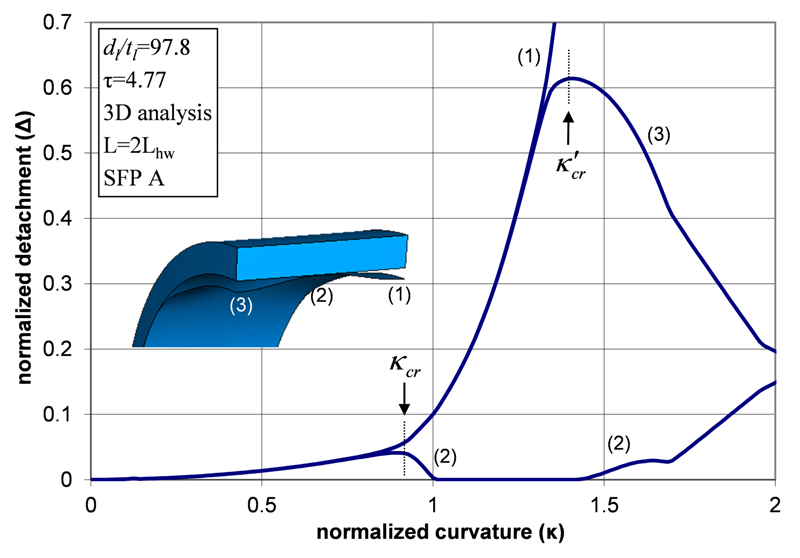

Figure 9: Detachment development of points (1), (2) and (3) in terms of bending curvature.

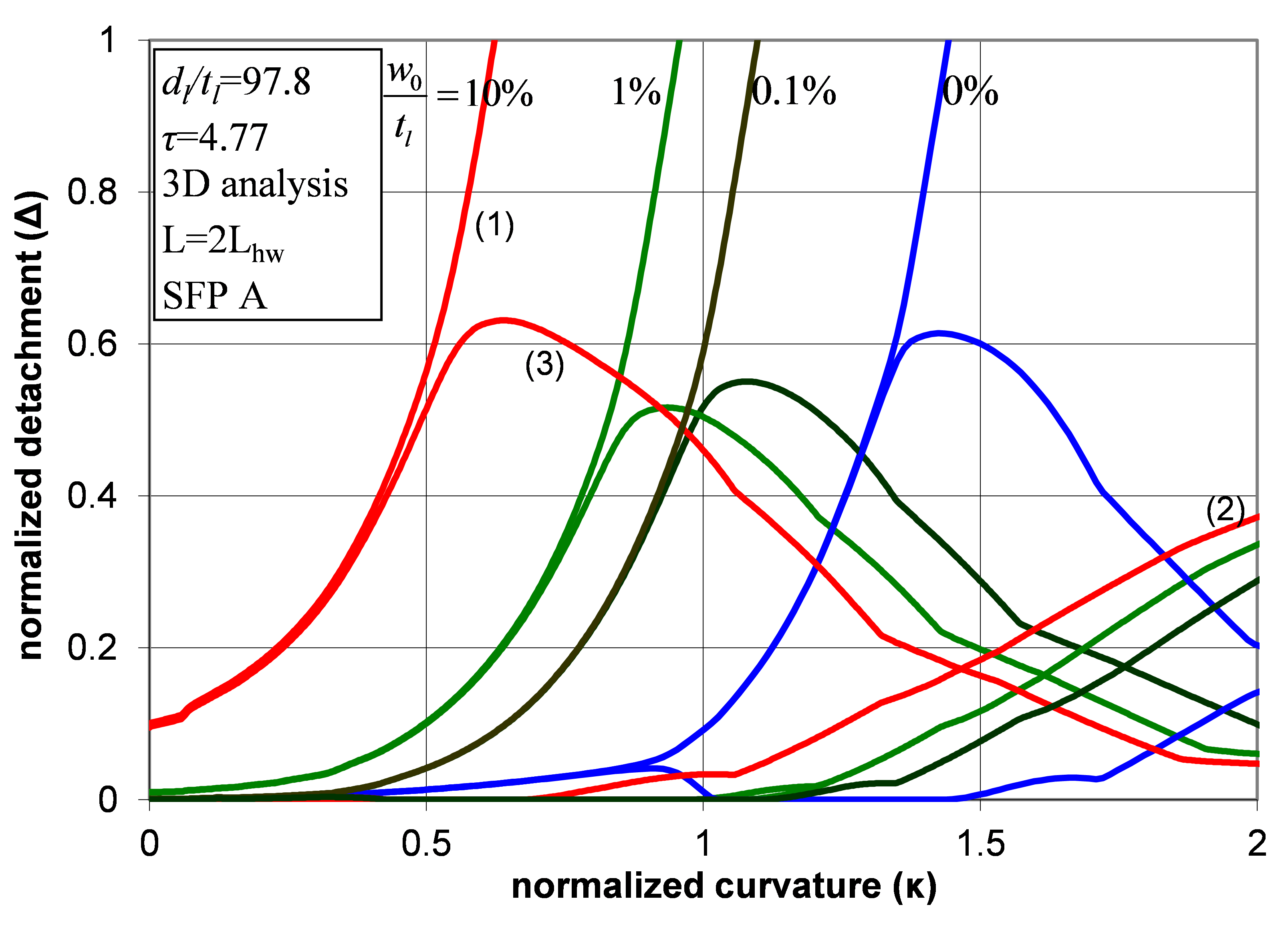

Figure 10: Detachment development of SF Pipe A for different values of the first mode imperfection amplitude.

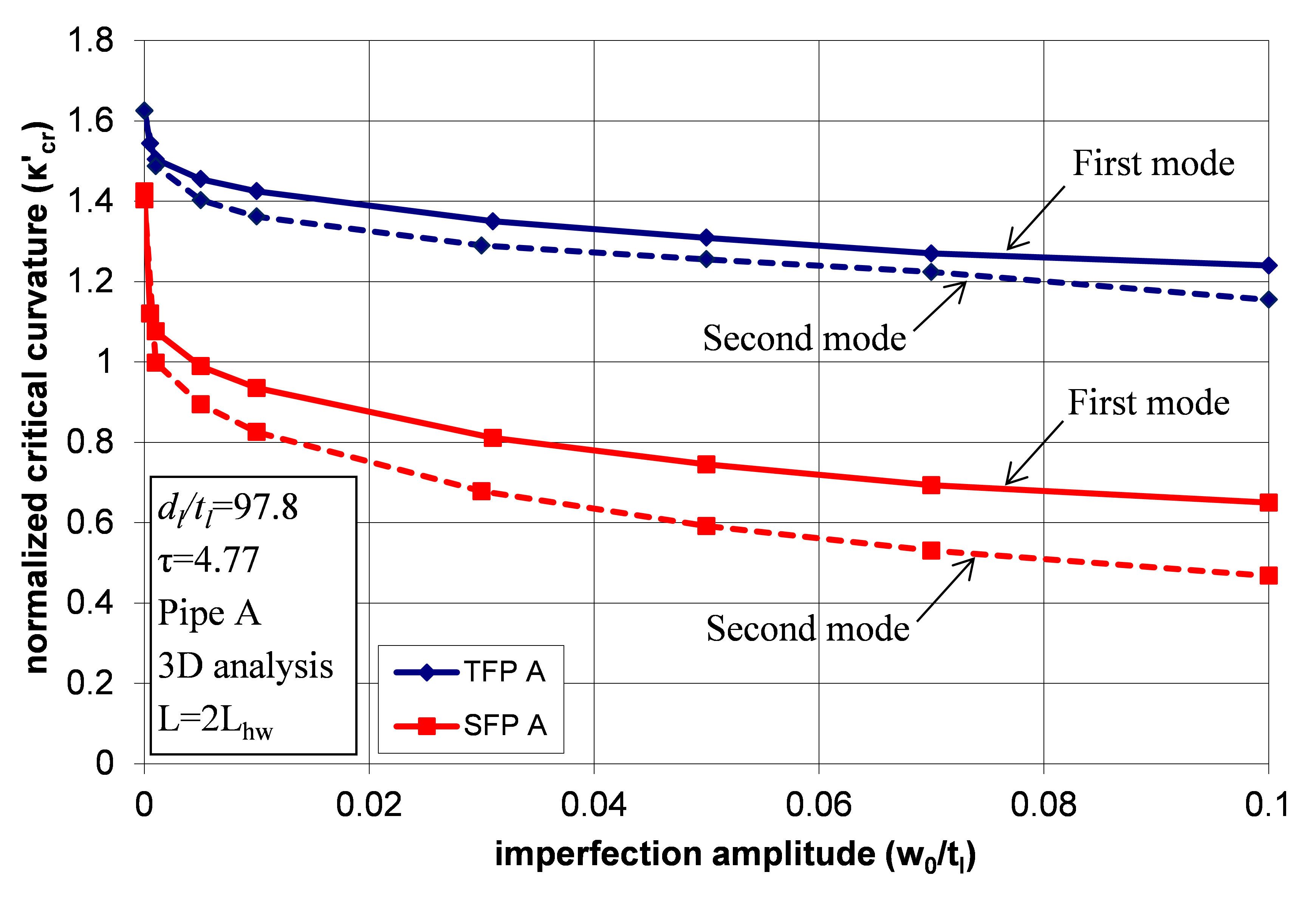

Figure 11: Effects of initial wrinkling imperfections on the value of secondary bifurcation curvature.

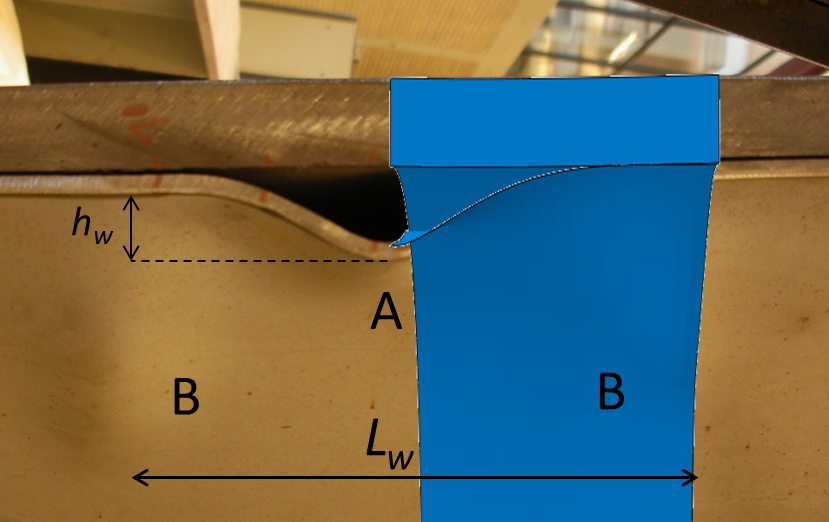

Figure 12: Photo of wrinkled specimen after experimental testing with image from finite element simulation.